How Are Inekon Trams Manufactured For USA Cities!

Your Virtual Visit to the Inekon Trams Factory.

The Inekon Trams that are manufactured for American cities; Seattle, Portland, Tacoma and Washington DC, have many design differences from models in service, in Czech cities; Ostrava and Olomouc.

Washington

Washington Seattle

Seattle

All trams are crafted according to the stringent specifications. Upon delivery in USA cities, all that is necessary is to place the trams on the rails, remove their protective packaging and mount the ticket machine. The Tram is ready to go!

How are the trams made? You can view the manufacturing process on the following factory photos.

The tram's body is welded using high-quality profiles made of rolled and pressed steel. The stringent material and workmanship requirements provide for a lifespan of 40 years. The steel profiles are made by a company CKD Kutna Hora

The front part of the tram's body is made of fiberglass laminates.

The roof rustproofing is guaranteed with the use of stainless steel.

Now is the time to attach the side panels, floor, and the assembly will go the paint room.

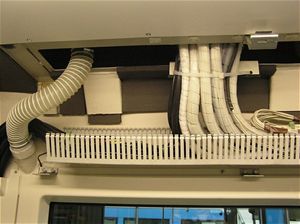

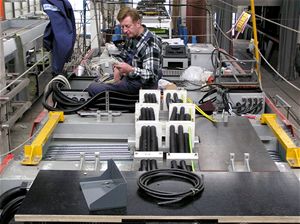

When the assembly is returned from the paint shop, the windows are mounted in the passenger's cabin, and it is a time for the electricians to come aboard. All tram's wiring is done with flame-retardant materials only.

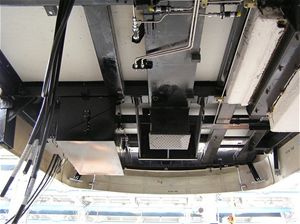

The low-floor section is attached to the sections containing bogies with a big joint.

The electric motors powering the bogies are connected with a dedicated traction device. On the photo, you see the space where bogie will be attached.

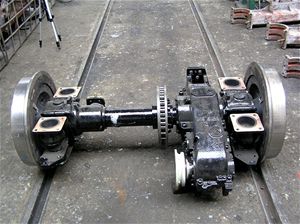

The hydraulic brakes attached to every bogie work independently. The brakes analyze the present friction conditions and adjust automatically. On the above photo, you can see bogie with a gearbox and radial brakes. The other picture shows the details of air cooling system for the radial brakes.

Most of the tram's electrical equipment is placed on the roof with a design to achieve maximum reliability in the service

Design Changes to Accomodate Requirements Of US Cities:

Trio trams for US customers have a stronger frame, bi-directional design, and especially adjusted bogies to keep the tram's height constant above the rail, during different occupancy load. The safety factors are also compliant with local regulations.

The lighting placement is bi-directional.

In the USA, the last piece of equipment is attached. It si the third part of ticketing machine. To pay the fare, you can use coins, (left side) paper notes (upper right part) or by a bank card (this part attached in the US and it is the right lower part).

Tram boarding is done on one side only.

The driver's cab are placed on both sides of the tram.

The tram's tachometer is in miles.

The low-floor section contains minimum seat placement to maximize the capacity to accommodate physically challenged people.

The passenger's communication device.

The physically challenged passengers can operate loading & unloading ramp.

The wheelchair loading ramp slides in and out by the electric motor.

The tram is equipped with an emergency brake that is operated by the pressure. You can just lean against it to stop the tram.

The passenger's compartment is fully air-conditioned.

How Do Trams Get to The USA?

Twenty meters long tram weighs almost 30 tons and travels by a freighter. For its journey, every tram is carefully prepared in the factory in the City of Ostrava. The tram is fully conditioned to resist effects of the sea salt, wrapped in the tight, protective cover. All electrical equipment is filled with humidity absorbing material. Because of the transport complexities, the tram is equipped with a special shock measuring device that monitors and records any shocks with and timings. The prepared trams are loaded on the truck and travels to the Port of Bremen in Germany.

The Trams Shipped to The USA Are Fully Operational!

Twenty meters long tram weighs almost 30 tons and travels by a freighter. For its journey, every tram is carefully prepared in the factory in the City of Ostrava. The tram is fully conditioned to resist effects of the sea salt, wrapped in the tight, protective cover. All electrical equipment is filled with humidity absorbing material. Because of the transport complexities, the tram is equipped with a special shock measuring device that monitors and records any shocks with and timings. The prepared trams are loaded on the truck and travels to the Port of Bremen in Germany.

The energized tram than rides approximately two km, along a testing track, where a team of specialists can tune the tram up. The front and end have different colors to let the passengers know, in which direction the bi-directional tram is moving. On the above photo, you can see fully energized tram for Portland, Oregon.